Views: 0 Author: Site Editor Publish Time: 2025-08-30 Origin: Site

In the world of textile decoration, Direct-to-Film (DTF) printing has quickly become one of the most versatile and efficient solutions. It allows businesses, designers, and hobbyists to print vibrant, durable designs and transfer them onto a wide range of fabrics and products. At Disen Company, we not only provide professional-grade DTF printers and heat press machines, but also offer comprehensive solutions that help customers start, grow, and enjoy their printing businesses with confidence.

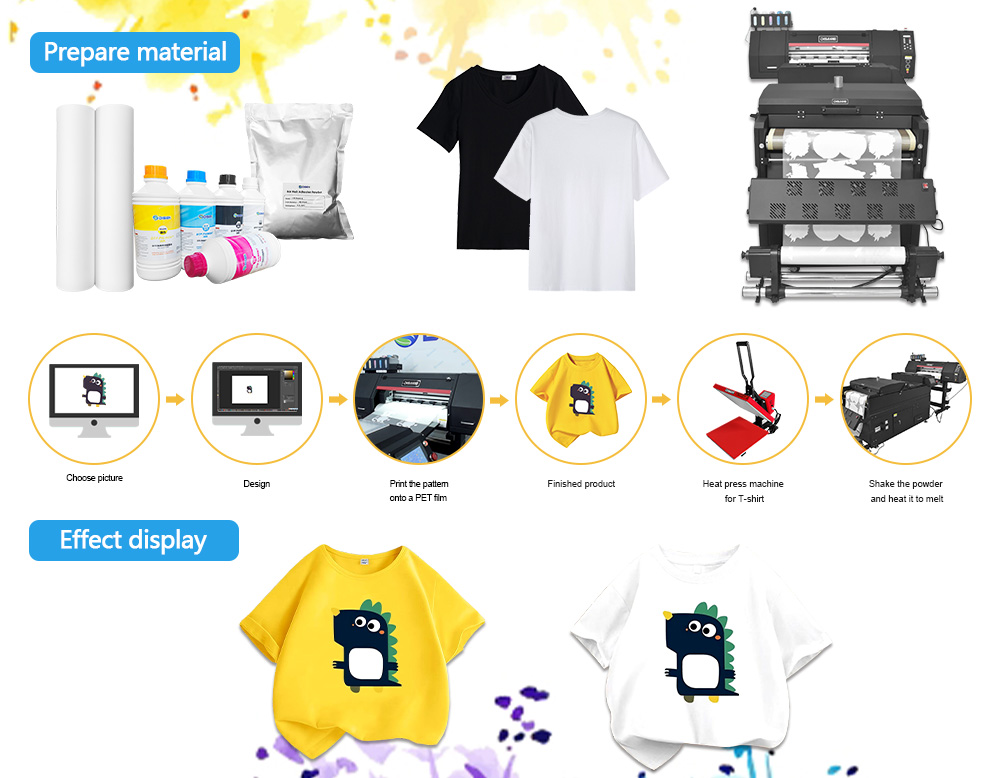

Every successful garment print starts with the right design. Customers can create their own artwork using graphic design software such as Adobe Illustrator, Photoshop, or CorelDRAW. DTF printing works with both simple logos and detailed, colorful images, making it suitable for fashion brands, promotional products, and personalized gifts.

At Disen Company, we understand that not all customers are experienced designers. That is why we provide file preparation guidance and offer technical support to ensure that your design files are compatible with the printer. Our team helps you adjust resolution, color profiles, and file formats, so that the final print is sharp and eye-catching.

Once the design is ready, it is printed onto a special PET film using the DTF printer. The printer applies colored inks precisely, followed by a layer of white ink to ensure the design stands out on both light and dark fabrics.

The DTF printer from Disen Company is built for high efficiency, stable operation, and vivid output. With our machines, customers can produce prints with consistent color quality and fine details. In addition, we provide training sessions and video tutorials to teach customers how to operate the printer, maintain it properly, and achieve the best results.

After printing, a layer of hot-melt adhesive powder is evenly applied on the wet ink surface. This powder is essential, as it bonds the ink to the fabric during the transfer process. Once applied, the film with powder is heated slightly, so the adhesive melts and attaches firmly to the design.

Disen Company supplies high-quality powders and consumables along with the printers, so our customers do not need to worry about sourcing materials. We also advise customers on proper storage and handling of consumables to maximize production efficiency.

The prepared DTF film is now ready for transfer. Using a heat press machine, the design is pressed onto the fabric at the correct temperature, pressure, and time. This step ensures that the design permanently bonds with the fibers of the material.

By using a heat press machine, customers can print patterns onto a wide variety of products:

T-shirts and hoodies

Pants and shorts

Caps and hats

Shoes and sneakers

Bags, scarves, and many other fabric-based items

This flexibility gives businesses the opportunity to expand their product range and increase profit margins. Our machines are designed for uniform heating, easy operation, and long service life, making them ideal for both beginners and experienced professionals.

Once the pressing process is complete, the PET film is peeled off, leaving behind a vibrant and durable design on the fabric. The result is a high-quality print that can withstand washing and daily use without fading or cracking.

Disen Company emphasizes not just selling equipment, but also ensuring that customers know how to handle every step effectively. We provide after-sales support, troubleshooting, and spare parts supply, so customers can continue production without interruption.

The process of creating garment prints with a DTF printer is simple but requires reliable equipment and professional guidance. At Disen Company, we go beyond just selling printers and heat press machines:

One-Stop Solution: Printers, powders, films, and heat press machines are all available in one place.

Technical Support: Free training, tutorials, and after-sales assistance ensure smooth production.

Global Service: We provide shipping, installation support, and consultation to customers worldwide.

Business Growth: With our solutions, customers can expand into custom fashion, promotional merchandise, and personalized gift markets.

DTF printing is reshaping the way designs are applied to textiles. With the right equipment and support, it opens endless opportunities for creative expression and profitable business. Disen Company is committed to delivering not only advanced DTF printers and heat press machines, but also complete solutions that help customers succeed in the textile printing industry.

By choosing Disen Company, customers are not just buying a machine—they are gaining a long-term partner who provides innovation, service, and reliability. Whether you want to print on T-shirts, caps, pants, or shoes, Disen Company ensures that your journey into garment printing is smooth, efficient, and rewarding.