Views: 0 Author: Site Editor Publish Time: 2025-12-24 Origin: Site

Embroidery has evolved far beyond traditional flat stitching. With the development of computerized embroidery machines, embroidery is now widely used in fashion, branding, personalization, and small business production. Among all embroidery techniques, 3D embroidery (also known as 3D puff embroidery) has become one of the most eye-catching and commercially valuable styles, especially on T-shirts and caps.

This article provides a complete, step-by-step guide—from basic embroidery applications to advanced 3D embroidery—helping beginners and embroidery lovers understand how to successfully create 3D embroidery on T-shirts and caps while also recognizing its growing market demand.

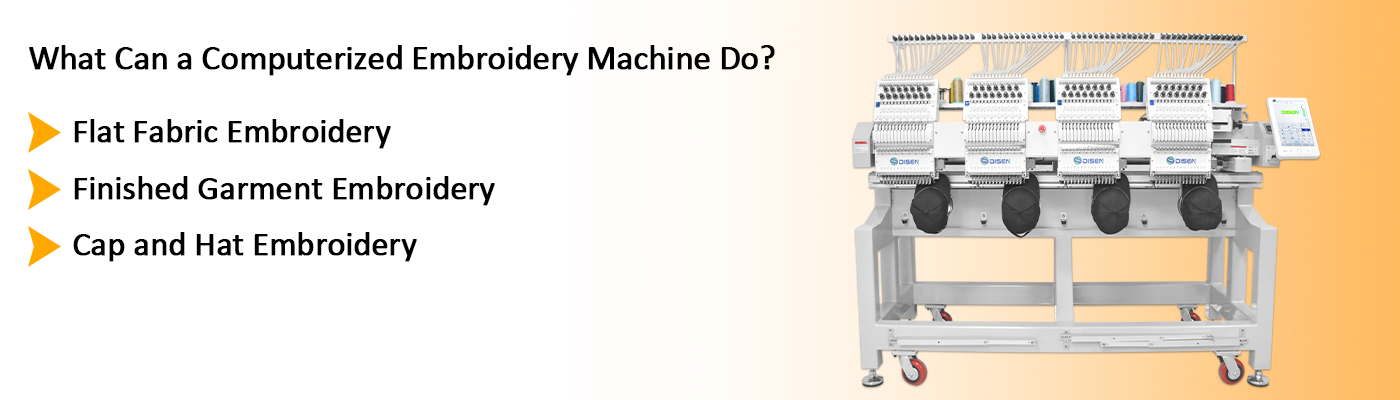

A modern computerized embroidery machine is a highly versatile piece of equipment. It is capable of handling a wide range of embroidery applications across different materials and finished products.

This is the most basic and common embroidery application. It includes:

Fabric panels

Cut pieces for garments

Denim, canvas, cotton, polyester, and blends

Flat embroidery is widely used in garment factories, home textiles, promotional products, and fashion accessories.

Also known as ready-made garment embroidery, this involves embroidering directly onto:

T-shirts

Polo shirts

Hoodies

Jackets

Sweatshirts

This type of embroidery requires proper hooping techniques and stabilizers to prevent fabric distortion, especially on elastic materials like T-shirts.

Cap embroidery is one of the most profitable applications in the embroidery industry. Common products include:

Baseball caps

Trucker hats

Snapbacks

Structured and unstructured caps

Cap embroidery usually uses specialized cap frames and requires precise control of tension, speed, and design layout.

As consumers seek more personalized, premium, and unique products, embroidery demand continues to grow. Compared with printing, embroidery offers:

Better durability

Higher perceived value

Strong brand identity

Fashion brands, sports teams, streetwear labels, corporate uniforms, and small customization studios all rely on embroidery to stand out in a competitive market. This demand has pushed embroidery beyond basic flat stitching toward more creative and high-impact techniques, including 3D embroidery.

3D embroidery, often called 3D puff embroidery, is a technique that creates a raised, three-dimensional effect on embroidered designs. This is achieved by placing EVA foam underneath the stitches, allowing the thread to wrap around and cut the foam during embroidery.

The result is a bold, textured design that visually and physically stands out.

Common Uses of 3D Embroidery:

Brand logos

Large lettering

Sports team names

Streetwear designs

3D embroidery attracts a specific and passionate audience:

Streetwear and fashion brand owners

Cap manufacturers and resellers

Embroidery hobbyists seeking advanced techniques

Small business owners offering premium customization

Sportswear and youth-oriented brands

These users value strong visual impact, texture, and uniqueness, making 3D embroidery especially popular among younger consumers and trend-driven markets.

Step 1: Master Basic Flat and Garment Embroidery

Before attempting 3D embroidery, operators should be comfortable with:

Hooping techniques

Stabilizer selection

Thread tension control

Speed adjustment

Design placement

This foundation ensures smoother results when moving to advanced techniques.

Step 2: Understand 3D Embroidery Design Requirements

3D embroidery requires special digitizing, not standard embroidery files.

Key design rules:

Use satin stitches only

Stitch width should be at least 3.5–4.0 mm

Stitch density should be high enough to cut the foam

Avoid small text, sharp corners, and fine details

Proper digitizing determines most of the final quality.

For T-Shirts:

Medium to heavy cotton or fleece

2–3 mm EVA foam

Cut-away or medium-heavy tear-away stabilizer

Water-soluble topping (recommended)

For Caps:

Structured caps with firm front panels

3–5 mm EVA foam

Cap frames

Medium to heavy stabilizer

Soft or overly thin fabrics are not ideal for 3D embroidery.

Step 1: Hooping and Preparation

Hoop stabilizer securely

Attach the garment or cap properly

Place the foam accurately over the embroidery area

Ensure no fabric stretching occurs

Step 2: Machine Settings (General Guidelines)

Slower speed than flat embroidery

Slightly looser tension for T-shirts

Proper presser foot height to clear foam thickness

Lower speeds allow cleaner foam cutting and reduce thread breaks.

Step 3: Embroidery Execution

Start embroidery carefully

Monitor thread tension and stitch formation

Avoid interruptions during satin stitch areas

After embroidery:

1. Tear away excess foam along stitch edges

2. Remove stabilizer and topping

3. Trim remaining foam carefully

4. Avoid high heat on raised embroidery areas

A clean finish enhances the 3D effect and durability.

3D embroidery offers:

Higher product value

Premium pricing opportunities

Strong differentiation from standard embroidery

High demand in caps and fashion markets

Many embroidery businesses find that 3D embroidery significantly increases profit margins, especially for branded caps and limited-edition apparel.

To successfully produce flat embroidery, garment embroidery, cap embroidery, and 3D embroidery, a reliable and versatile embroidery machine is essential.

When selecting an embroidery machine, look for:

Stable stitching at high density

Compatibility with cap frames

Adjustable speed and tension

Strong motor performance

Support for different embroidery applications

Manufacturers such as Disen Machinery provide embroidery machines designed for multi-application use, including flat embroidery, garment embroidery, cap embroidery, and advanced techniques like 3D embroidery. These machines are suitable for embroidery factories, customization studios, and entrepreneurs looking to expand their product range.

3D embroidery represents the next level of creative and commercial embroidery. By mastering basic embroidery techniques, understanding specialized digitizing, using the right materials, and operating a capable computerized embroidery machine, anyone can successfully apply 3D embroidery to T-shirts and caps.

As market demand continues to grow and consumers seek more distinctive products, 3D embroidery offers both artistic satisfaction and strong business potential—making it a valuable skill for embroidery lovers and professionals alike.